Inspection on WS of Austenitic stainless steel

Austenitic stainless steel is a kind of stainless steel with stable austenitic structure at room temperature. The structure has the advantages of non-magnetic high toughness high plasticity strong chemical and electrochemical corrosion resistance heat resistance high temperature resistance low temperature resistance and even ultra-low temperature resistance which makes austenitic stainless steel widely used in daily life. With the wide application of austenitic stainless steel nondestructive testing is becoming particularly important.

As austenitic stainless steel is an object that is difficult to be detected by ultrasonic the austenitic stainless steel weld does not undergo phase transformation during solidification and still exists as cast columnar austenitic grain under normal temperature. This kind of material will cause serious attenuation of ultrasonic propagation which brings many difficulties to ultrasonic flaw detection.

Our phased array TFM real-time 3D ultrasonic imaging system CTS-PA322T has the advantages of high intensity total focus performance higher signal-to-noise ratio higher defect detection rate higher detection accuracy and greater sound field coverage effectively reducing the blind area and improving the detection efficiency of girth weld of austenitic stainless steel thick-walled pipe.

CTS-PA322T is a new 64 channel fully parallel phased array total focus (TFM) real-time ultrasonic imaging detection system independently developed by our company. The system collects the FMC data in real time and uses the high-speed hardware imaging technology based on FPGA operation to realize the high-precision real-time 2D / 3D total focus (TFM) imaging detection of metal and non-metal materials. The first industrial phased array RF metadata platform can directly process the complete original data by computer.

Inspection cases of austenitic stainless steel welds:

> 3D TFM Inspection of Circumferential Weld of 70mm Austenitic Stainless Steel Pipe.

Due to the the coarse grain and anisotropic structure of austenitic stainless steel weld which leads to the scattering and distortion of the ultrasonic beam the penetration of conventional ultrasonic testing is insufficient and the testing is difficult. Using phased array TFM real-time 3D ultrasonic imaging system CTS-PA322T and austenitic stainless steel special probe to detect the circumferential weld of large thick-walled austenitic stainless steel pipe fittings real-time 3D total focus (3D-TFM) imaging detection is realized for the weld area 3D-TFM combined with encoder with continuous scanning can form a stereoscopic and intuitive 4D detection image for the entire weld area which effectively improves the sensitivity and penetration and provides an effective inspection method for the girth weld of large thick-walled austenitic stainless steel pipe.

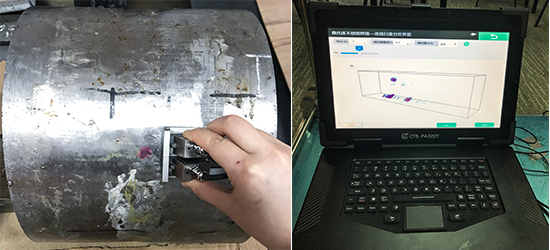

70mm austenitic stainless steel pipe fittings

3D TFM imaging inspection

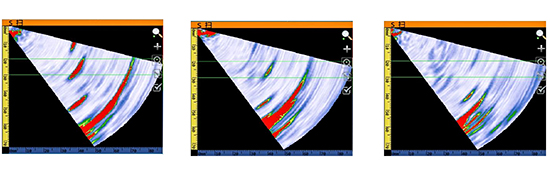

Real time 4D inspection image:

It can be seen from the above figure that there are obvious defects and root echo in the girth weld of large thick-walled austenitic stainless steel pipe fittings the 3D TFM real-time imaging detection results are intuitive and the defect reconstruction distortion degree is small.

Analysis interface of Continuous scanning:

3D-TFM inspection imaging analysis function can accurately locate and quantify the defects of austenitic stainless steel welds.

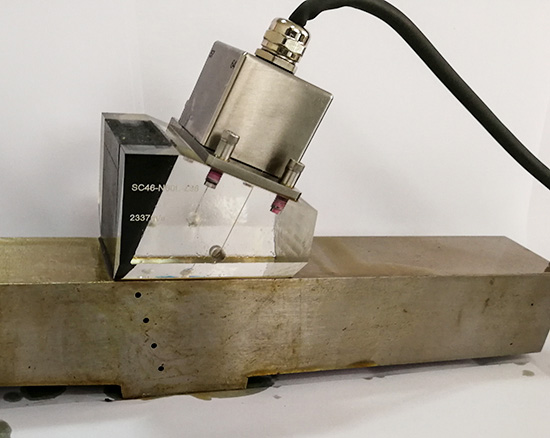

> 3D TFM Inspection of 70mm Austenitic Stainless Steel Weld Seam Test Block

The traditional PA imaging inspection technology and 3D TFM technology are used for the comparative test. The results show that the 3D TFM real-time imaging inspection results are intuitive the defect reconstruction distortion degree is small the defect detection ability is strong and the defects in the opposite fusion line will not be missed when the cross weld detection is adopted.

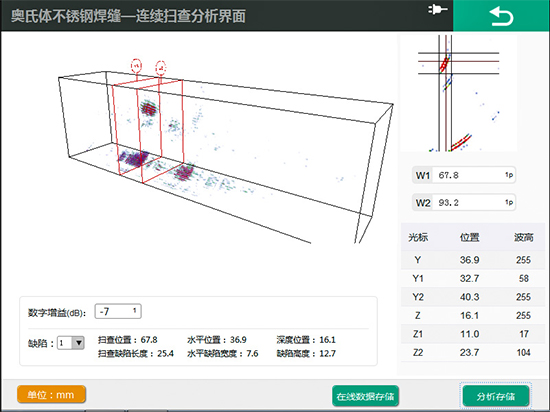

70mm austenitic stainless steel weld

Diagram of artificial defects in welds

S- scan image

3D TFM real-time imaging

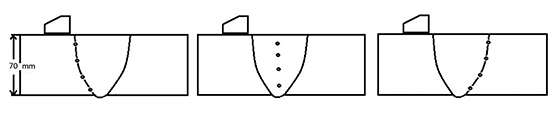

> 3D TFM Inspection of Girth Welds of Large Thick-wall Austenitic Stainless Steel Pipes

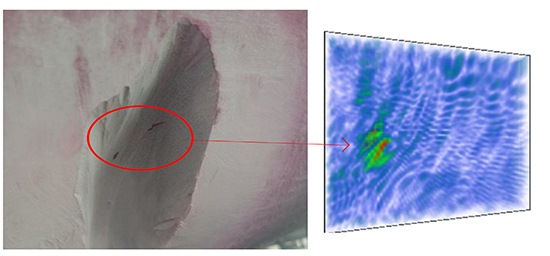

Testing site

Diagram of detection results of burial cracks

According to the results of penetration testing it can be seen that there is a crack defect in the weld of large thick-walled austenitic stainless steel. Compared with the 3D TFM inspection image the detection results of the two are basically consistent. It can be judged that the defect is a burial crack. Experimental data show that 3D TFM inspection can effectively detect the internal crack defects in the weld of large thick-walled austenitic stainless steel and the detection results are true and effective.

Advantages of 3D TFM technology in detecting austenitic stainless steel weld test block:

● Intuitive detection result small distortion degree of defect reconstruction

● Strong defect detection ability to avoid missed inspection

● Accurate defect location and quantification support online / offline analysis

● Real-time and fast detection high imaging accuracy