The CTS-PA22T1 is a new 64 channel full parallel phased array total focusing (TFM) fast ultrasonic imaging detection system independently developed by our company.

The CTS-PA22T1 is a new 64 channel full parallel phased array total focusing (TFM) fast ultrasonic imaging detection system independently developed by our company. The system collects FMC data in real time and uses high-speed hardware imaging technology based on the signal processing chip to achieve high-precision real-time phased array 2D / 3D total focusing (TFM) imaging detection of metal and non-metal materials.

The industrial phased array RF metadata platform which can directly process the complete original data by computer.

Total focusing (TFM) reconstruction algorithm model

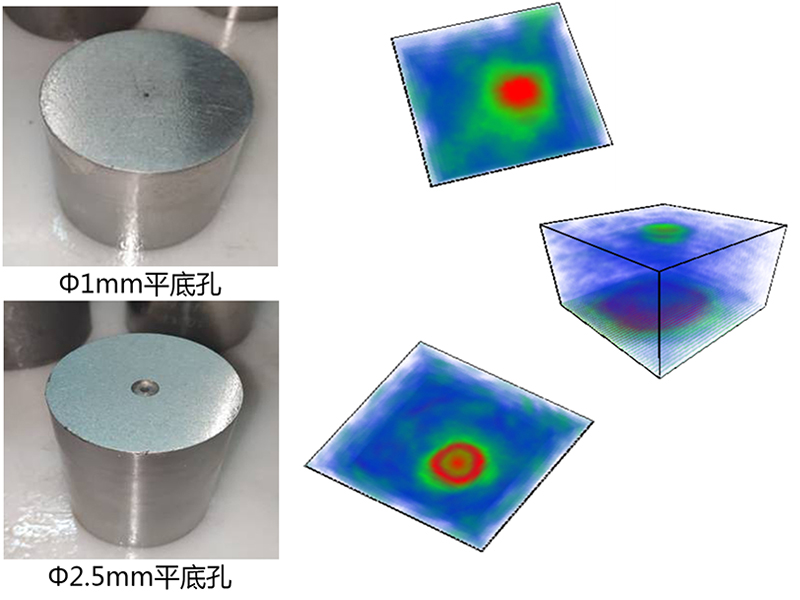

According to the reconstruction algorithm model of total focusing (TFM) the high-speed hardware imaging technology based on the signal processing chip is used to calculate the results of the total focusing (TFM) image in real time and the image update rate can reach 50fps.64 fully parallel phased array hardware channels

With 64 fully parallel phased array hardware channels it can collect up to 4096 FMC data of type A waves in real time with a sampling depth of 2m.Real time total focusing (TFM) imaging detection

Support rapid imaging detection of aerospace composite materials high-speed rail line butt welds wheel rims and axles of electric locomotives wind turbine blade bolts and thick wall butt welds.Fast C-scan imaging

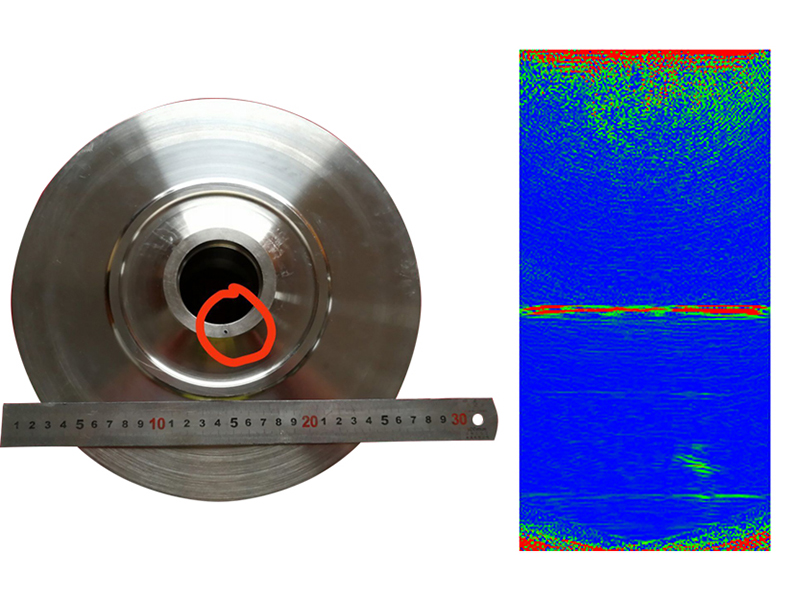

Based on 2D total focusing (TFM) combined with encoder positioning fast C-scan imaging can be realized for the detected materials.- 3D transverse wave total focusing (TFM) module

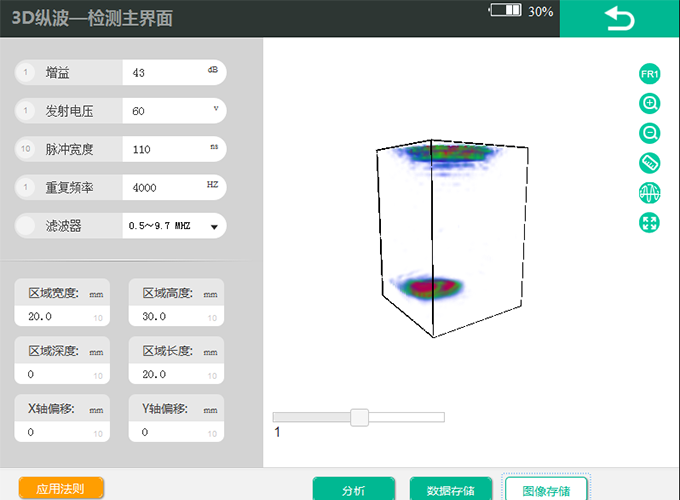

Based on the two-dimensional array probe and corresponding wedges the real-time detection of the weld area can be realized to form a stereoscopic 3D graphic display; 3D-TFM combined with the encoder can form an intuitive and transparent 4D detection image of the weld area. - Multiple 3D-TFM modes

A variety of TFM solutions for welds castings and forgings; an ideal alternative for RT inspection of medium and thick-walled austenitic stainless steel welds. - Real time 4D detection

3D-TFM combines with encoder to form real-time 4D detection image and the scanning speed is up to 100 mm / s. - TFM detection of special workpiece

For different workpieces to be inspected the self defined total focusing model can realize the effective TFM detection of various special materials such as plexiglass spherical shells ceramics and other workpieces. - Original data storage and report generation

The system provides functions such as original full matrix data storage and test results storage quantitative analysis of defect location etc. it can provide test reports according to the report format required by users.

| Pulser | |

| TX | Bipolar square wave 45V~100V tunable with 1.0V 10.0V per step |

| Pulse Width | 30~600ns with 1.0ns 10.0ns per step |

| Reciver | |

| Bandwidth | 0.5~20.8MHz |

| Gain Range | 0~55dB with 1.0dB 10.0dB per step |

| Filter | Low/mid/high |

| Data Processing | |

| Digitizing Rate | 62.5 MHz,10 bit |

| Input Impedance | 50Ω |

| Delay | 0~40 μs,P:2.5ns |

| Focal laws(Qty) | 262144 |

| In-Built Processer | Large chip big data real-time HW processing |

| System | |

| Channel Config | 64x64 total in parallel |

| Power Consumption | 50W |

| Operation Platform | Above Windows7 |

| Signaling Rate | 100M/1000M Ethernet |

| Dimension | 395×283×66 |

| Weight | 3.1Kg |

| I/O | |

| PA Probe Connector I-PEX | |

| LAN network | |

| I/O | |

| USB2.0 port(Qty):2 | |

| ENCODER port | |