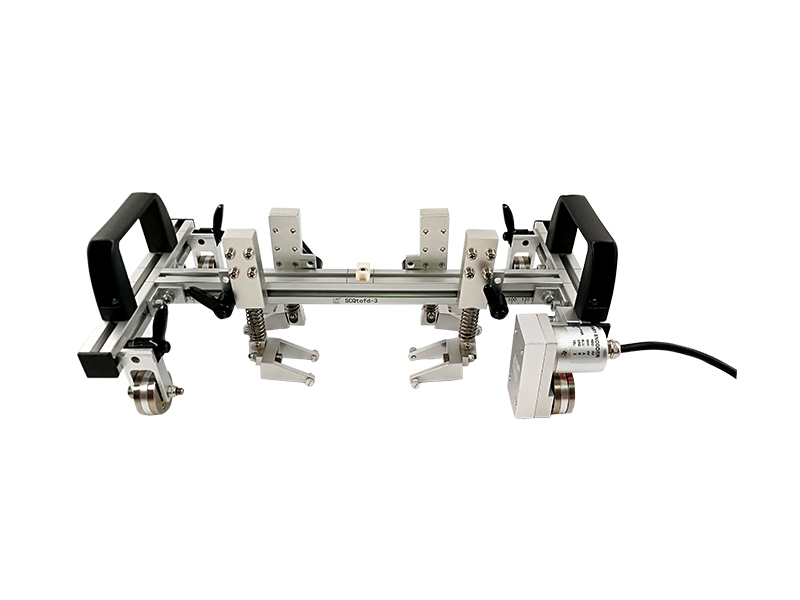

The SCQtofd-3 scanner is designed by I-type structure and provides four magnetic wheels for adsorption, which can be installed simultaneously by four scanning fixtures.

The SCQtofd-3 scanner is designed by I-type structure and provides four magnetic wheels for adsorption, which can be installed simultaneously by four scanning holders. It is an ideal scanner for inspection of dual-channel TOFD flat welds and pipeline girth welds with thickness less than 100mm. The SCQtofd-3 is used as a standard scanner for CTS-2009 ultrasonic flaw detector.

H structure, convienient installation and adjustment.

The fixture beams have PCS adjustment scale of screen printing.The PCS value adjustment is convinient.

Magnetic suction function, the perfect coupling, walks smoothly by pushing with both hands.

Using modular design, it can be extended to realize more channels TOFD scan.

| PCS Stretch | Matched with TOFD wedges (front edge: 8mm) manufactured by Goworld, the PCS adjustment range of 20mm~300mm (user customizable). |

| Encoder accuracy | 5 step/mm |

| Encoder Interface | Industry-standard encoder interface complies with the new rules and other TOFD testing standards. |

I. It can realize single channel TOFD detection, dual channel TOFD detection, single channel TOFD + dual channel PE detection, four channel PE detection.

II. The TOFD scan mode is nonparallel.

III. It is especially suitable for flat weld and pipeline girth weld detection.

IV. Combined with CTS-1008plus or CTS-2009 ultrasonic flaw detector.