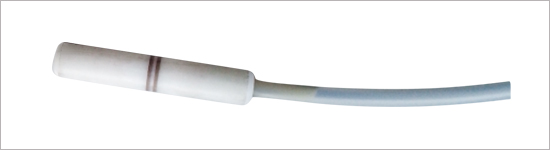

Probe for special purpose could be customized. Appearance of ET probe can be refered to the outline of the workpiece, or the right position the probe is fixed in the holder, which guarantee fast and accurate detection.

Probe for special purpose could be customized. Appearance of ET probe can be refered to the outline of the workpiece, or the right position the probe is fixed in the holder, which guarantee fast and accurate detection.

For different detection objects, the eddy current detection probe designed with good excitation and reception structure, connecting with eddy current detector to obtain the best matching performance and highest detection sensitivity.

The probe interface adopts plug-in method, which makes the probe smaller and faster to replace.

Weld Probe

Edge-purposed Probe

Surrounding Probe

Penetrating Probe

Specifications:

| Description | Frequency | Type |

| Pen-type Shielded Probe | 50~500K | Differential |

| Pen-type Shielded Probe | 500k~3M | Differential |

| Pen-type Non-Shielded Probe | 50~500K | Differential |

| Pen-type Non-Shielded Probe | 500k~3M | Differential |

| RT Probe | 50~500K | Absolute |

| RT Probe | 50~500K | Differential |

| RT Probe | 500k~3M | Absolute |

| RT Probe | 500k~3M | Differential |

| Weld Probe | 30k~100kHz | Absolute |

| Edge-purposed Probe | 50~500K | Differential |

| Edge-purposed Probe | 500k~3M | Differential |

| Surrounding Probe | 1k~50k | Customization |

| Penetrating Probe | 1k~50k | Customization |

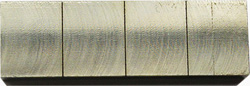

Auxiliary Test Block:

stainless steel

aluminium

Applications:

Metal surface and subsurface damage detection in aerospace, nuclear energy, military, railway, power petrochemical, metallurgy, etc.