With the wide application of forgings in high-end equipment manufacturing industry higher requirements are put forward for the quality level of forgings and the technical requirements for nondestructive testing of forgings are becoming more and more strict!

We Goworld newly launched a real-time 3D total-focusing ultrasonic phased array imaging system which can realize the effective detection of different complex forgings. The imaging is intuitive stable and reliable which is the security guarantee for the operation of high-end equipment manufacturing industry......

Real-time 3D total-focusing ultrasonic phased array imaging system is used to realize real-time 3D imaging inspection of forgings which will bring you a different inspection experience!

1. A182 F22 alloy steel forging

A182 F22 alloy steel forgings with natural shrinkage defects inside. The 3D inspection image perfectly shows the structural shape of the workpiece and the shrinkage defects in the workpiece are also clearly presented.

F22 stainless steel forging and 3D inspection image

Image can be rotated 360°.

3D image 360° rotation effect

2. 410 stainless steel forging

410 stainless steel forgings with natural cracks inside. In the 3D inspection image we can easily determine the location of the crack defect and its overall shape.

410 stainless steel forging and 3D inspection image

3D image 360° rotation effect

3. 15-5PH stainless steel forgings

15-5PH stainless steel forgings have visible cracks at the side depression. In the 3D inspection image the 3D image structure of the groove and the crack extending from the side to the inside of the forging can be seen clearly.

15-5PH stainless steel forging and 3D inspection image

3D image 360° rotation effect

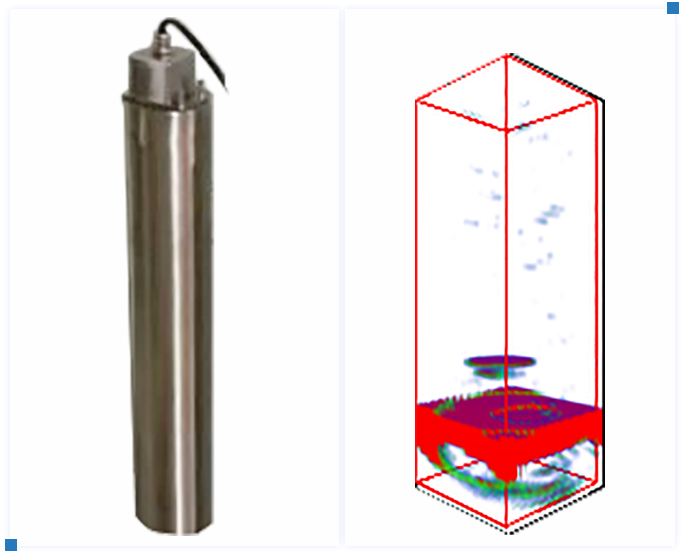

4. Nickel-based alloy forgings

Nickel-based alloy forgings with high attenuation performance 420mm in height and the artificial flat-bottomed hole with a diameter of Φ 3mm is processed at a depth of 400mm. In 3D inspection image the size and depth of the flat-bottomed hole can be accurately obtained.

Nickel-based alloy forgings and 3D inspection images

Offline analysis

Real-time 3D total-focusing ultrasonic phased array imaging technology can easily realize rapid and effective inspection of forgings improve defect interpretation! Goworld real-time 3D total-focusing ultrasonic phased array imaging system provides a more advanced and complete mothod for forging quality inspection you deserve it.