1. Study on the inspection of plexiglass spherical shell

In view of the crack defects of a special material (sound velocity is about 3000m / s) in the field of nuclear power, a domestic research institute now uses the CTS-PA22T phased array TFM real-time 3D ultrasonic imaging detection system to detect, which is newly designed by Guangdong Goworld Co., Ltd. Ultrasonic instrument branch, and a plexiglass ball test block is processed to simulate this special material. The spherical shell has a diameter of 150 mm and a thickness of 30 mm. Two open grooves with a depth of 5mm and 10mm are respectively processed on the outer surface to quantitatively detect the height of the open groove.

2. Detection system of plexiglass spherical shell

CTS-PA22T

3. Detection conclusion of plexiglass spherical shell

Due to the unprocessed curvature of SC7-N55S wedge, 2D-TFM was used to detect the end face of 25 mm thick plexiglass plate test block. From the 2D-TFM detection image, it can be seen that the upper and lower parts of the end face are effectively reconstructed.

2D-TFM detection image

Using 3D-TFM detection, the quantitative detection result of 5mm open groove is 5mm, and the quantitative detection result of 10mm open groove is 10mm. The measurement result is consistent with the actual defect size.

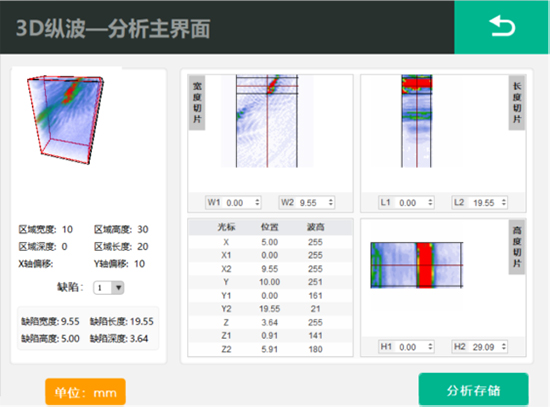

3D-TFM detection image

3D-TFM detection image