1 The Principle of Phased Array Ultrasonic Testing of Composite Material Adhesion

1.1 Phased array transmitting and receiving

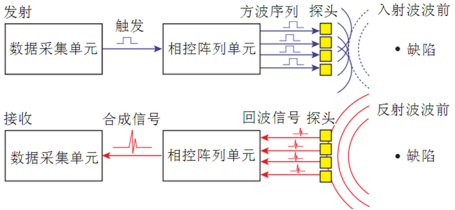

The transmitting and receiving principle of phased array ultrasonic is shown in the figure. When transmitting, the data acquisition unit triggers the phased array unit, and the phased array unit triggers the excitation square wave pulse to excite the probe in turn according to the set delay law, so as to focus the ultrasonic wave emitted by each element in the probe at a certain point.; when receiving, the ultrasonic waves reflected by the defect reach each receiving element, according to the echo signal of each receiving element, the phased array unit can be combined into a signal and transmitted to the data acquisition unit. Therefore, every time the phased array is transmitted and received, it will obtain an A-scan signal synthesized by the multi-element acquisition signal. Through electronic scanning technology, the phased array ultrasonic inspection can realize the display of the workpiece cross-sectional image.

Phased array transmitting and receiving

1.2 Phased array electronic scanning

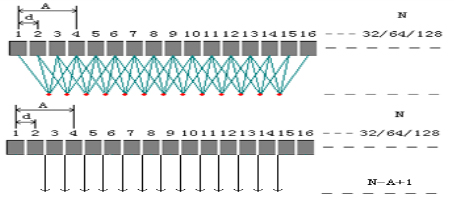

Phased array ultrasonic has unique electronic scanning and focusing, so a multi element phased array probe can be used to scan and detect the cross-section of the workpiece without moving the probe. This solution uses linear scanning and uses different element groups of the phased array probe with the same aggregation rule. By changing the position of the activated element, the sound beam is moved back and forth along the direction of the element array to achieve a forward and backward movement similar to conventional manual ultrasonic detection probe. The principle of linear scanning is shown in the figure.

Principle of linear scanning

1.3 Phased array C-scan imaging

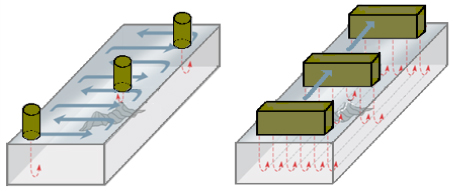

Electronic scanning with phased array can scan a certain width of the workpiece without moving the probe. Therefore, compared with the conventional sawtooth scanning method of single element probe, phased array scanning can obtain the C-scan image of the workpiece only with a single axis linear scanning. Therefore, for the welding seam of automobile wheel hub, only the probe is placed at the welding seam position, and the scanning inspection of phased array can be completed after the wheel hub rotates for one circle.

Conventional scanning and phased array scanning

2 Phased array ultrasonic testing system for Composite Material Adhesion

2.1 Overall technical solution of the system

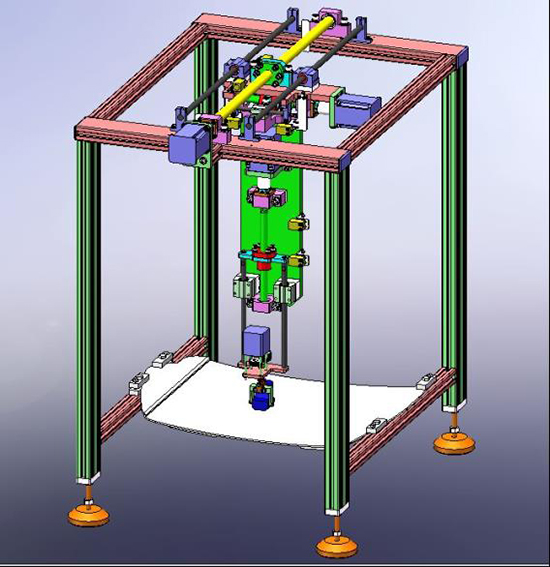

The 3D diagram of the overall technical solution of the system is as shown in the figure. A three-axis movement control platform is used to control the probe to move zigzagly to achieve the C-scan imaging detection of the whole workpiece. The instrument adopts phased array imaging detector to support ultrasonic A / B / C scanning imaging; the imaging software system is based on PC platform and provides complete software operation functions. The detection system is equipped with manual (including continuous and inching) control and automatic scanning control functions, and has the structure of up & down and front & back adjustment required by the probe. It has abnormal alarm and emergency protection measures to meet the needs of composite C scanning inspection for customers.

3D diagram of overall technical solution of the system

2.2 Brief description of other parts of the equipment

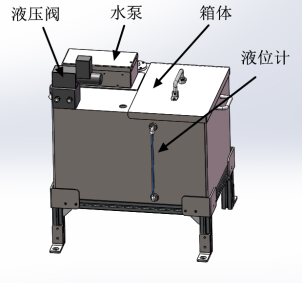

Water tank:

Water tank, as shown in the figure, is separate from the rotating platform. With capacity of 31L. It has its own hydraulic pump and controls the water supply of the equipment by controlling the hydraulic valve. In addition, the water used for scanning is not recycled.

Water Tank

Phased array instrument:

The CTS-PA22X is a modular ultrasonic phased array detection platform supporting secondary development. It integrates advanced technologies such as precision analog circuit, high-speed digital circuit, phased array signal processing, software system, network, etc. it can be widely used in phased array ultrasonic detecting of various workpieces.

CTS-PA22X

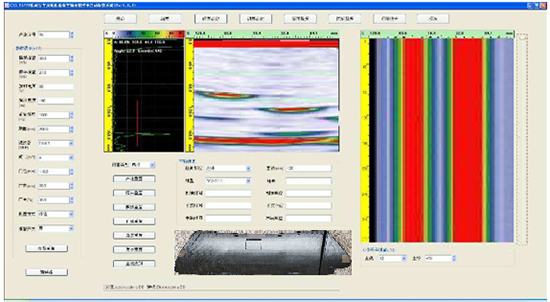

2.3 Introduction of detection software interface

Detection software interface